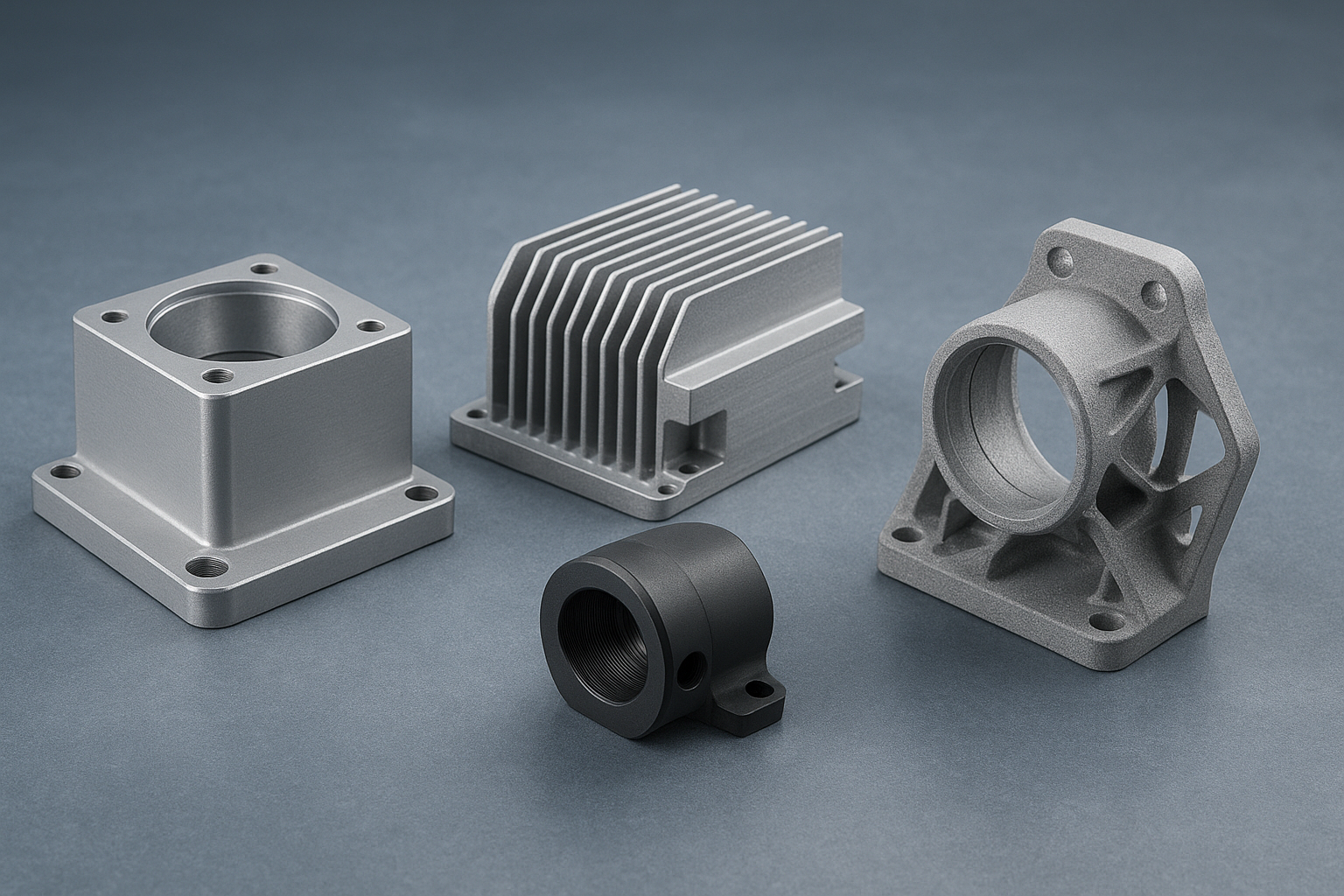

We specialize in the custom manufacturing of high-performance laser components and precision metal parts through advanced CNC machining, die casting, injection molding, and industrial 3D printing. Whether you need prototype development or full-scale production, we transform your designs into reliable laser components that meet the most demanding specifications.

Core Manufacturing Capabilities for Laser Components

Our comprehensive manufacturing services cover the entire product lifecycle for critical laser components:

-

Precision CNC Machining: For high-tolerance structural laser components, mirror mounts, optical housings, and heat sinks

-

Metal Die Casting: For lightweight, high-strength aluminum enclosures and thermal management laser components

-

Injection Molding: For high-volume production of plastic optical laser components, lens holders, and mechanical housings

-

Industrial 3D Printing: For rapid prototyping of laser components, complex internal cooling structures, and custom fixtures

Key Laser Components We Manufacture

We produce essential laser components that form the foundation of optical systems across multiple industries:

1. Mechanical Housings for Beam Shaping Laser Components

-

Manufacturing Process: Precision CNC machining + anodizing

-

Application: Integrated mechanical platforms for beam shaping laser components including collimators and homogenizers

-

Your Benefit: High-precision alignment surfaces ensure optimal performance of integrated optical laser components

2. Thermal Management Laser Components

-

Manufacturing Process: Aluminum die casting / Precision CNC

-

Application: Heat sinks and cooling systems for high-power laser components including single emitters and laser bars

-

Your Benefit: Superior thermal management laser components that extend diode lifetime and maintain stability

3. Fiber Coupling Laser Components

-

Manufacturing Process: Micron-level CNC machining + injection molding

-

Application: Precision fiber coupling laser components including connectors, lens barrels, and alignment mechanisms

-

Your Benefit: Critical laser components manufactured with exceptional coaxial accuracy for maximum coupling efficiency

4. Custom Mounting Laser Components

-

Manufacturing Process: CNC machining, 3D printing for rapid prototyping

-

Application: Specialized mounting laser components for optical elements in research and industrial systems

-

Your Benefit: Custom-designed laser components that maintain precise alignment under varying environmental conditions

5. Prototype Laser Components

-

Manufacturing Process: Industrial 3D printing + CNC machining

-

Application: Rapid development of prototype laser components for testing and validation

-

Your Benefit: Quickly iterate and refine your laser components before committing to production tooling

Why Choose Our Laser Components Manufacturing

-

Dedicated Laser Components Expertise: Deep understanding of the specific requirements for high-performance laser components

-

Comprehensive Laser Components Portfolio: From structural laser components to optical mounts and thermal solutions

-

Quality-Assured Laser Components: Rigorous inspection processes ensure every delivered laser components meets specification

-

Design for Manufacturing for Laser Components: Our engineering team optimizes your laser components designs for manufacturability and cost-effectiveness

We're Your Laser Components Manufacturing Partner

If you're looking for a reliable manufacturing partner for your critical laser components - from initial concept to volume production - contact us today for a free manufacturing feasibility analysis and quote. Let us help you build better laser components through superior manufacturing.

Share:

How Ultra-Precision Optical Lenses Are Made — The Finishing Touch of Precision Optical Coating

Why Aluminum Die Casting Is the Go-To Choice for Complex Metal Parts