Modern production lines don’t just need parts that “fit”—they need parts that stabilize OEE, survive vibration, and maintain alignment after thousands of cycles. That’s why buyers choose CNC Machining for Industrial Equipment at XY-GLOBAL. We turn drawings into robust, repeatable components: optical brackets that hold calibration, shafts that keep noise down at high RPM, valve bodies that seal the first time, and housings that assemble without rework.

What makes our parts “industrial-grade”?

-

Dimensional repeatability at scale. We lock down processes so the 500th part behaves like the 5th, not just on CMM but on your line.

-

Stability under load. Brackets and frames are designed to resist creep, thermal drift, and resonance—because a “0.02 mm wobble” can become a week of downtime.

-

Finish that’s functional. Ra ≤ 0.01 µm on sealing or optical-adjacent faces; controlled break-edges for safe, quick assembly.

-

Traceability by default. Heat lot, incoming inspection, and process parameters are recorded; inspection reports provided as required.

Capabilities at a glance

| Area | Highlights |

|---|---|

| Milling | 3–5-axis, thin-wall strategies, multi-face geometries, fixturing for low distortion |

| Turning | cnc machining turning for shafts, bushings, rollers, custom fasteners; tight TIR and coaxiality control |

| EDM & Grinding | Wire/EDM for slots & internal corners; OD/ID/surface grinding and lapping for fits & flatness |

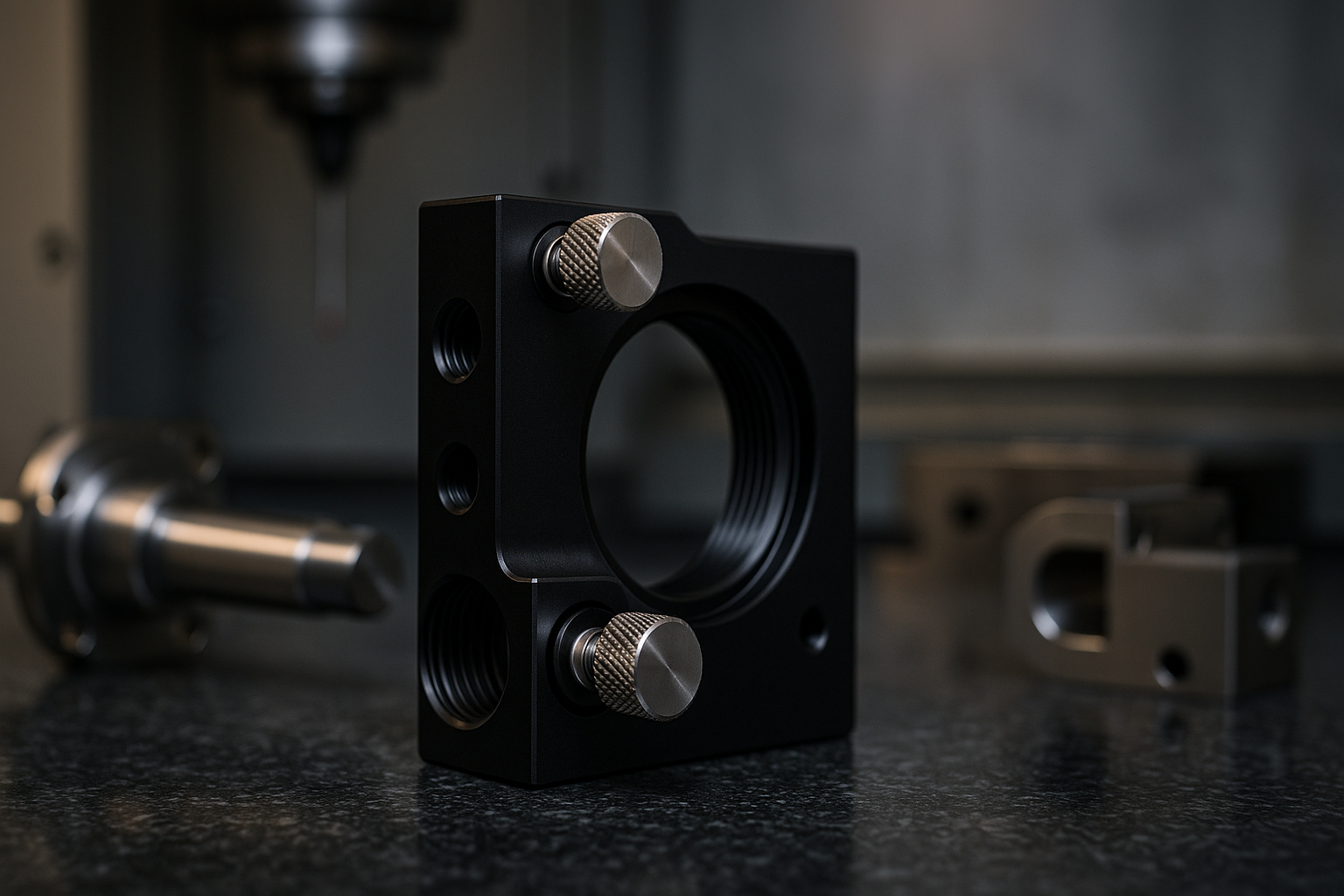

| Optical-adjacent | cnc machined optical brackets, mirror/rail interfaces, lens cells, low-glare blackening |

| Precision optics hardware | cnc machining precision optical components: collimator seats, prism clamps, filter retainers |

| Finishes | Hard anodize, black oxide, electroless nickel, DLC/TiN, bead blast + anodize, laser marking |

| Quality | CMM, vision metrology, gauge R&R, SPC on critical-to-quality (CTQ) features |

| Speed | Zero MOQ; rapid sample in as fast as 1 day (part-dependent) |

| Standards | ISO 9001:2015 & ISO 13485:2016; RoHS/REACH documentation available |

Where our machining moves the needle

1) Machine vision & automation cells

-

Problem: calibration drift and micro-vibration lead to false rejects.

-

Solution: high-stiffness cnc machined optical brackets with pin-bore datums and dual-face references; low-gloss, low-reflectivity surfaces to reduce flare; aligned through-holes for cable relief and strain relief.

-

Result: faster first-time calibration, fewer re-tunes after maintenance.

2) Motion & power transmission

-

Problem: noise and heat at higher throughput.

-

Solution: cnc machining turning with controlled roundness and runout; sequence heat-treat → grind to manage residual stress; tolerance-matched fits for bearings and couplings.

-

Result: longer bearing life, lower SPL, and fewer unplanned stops.

3) Fluid & pneumatic control

-

Problem: intermittent leaks and thread galling.

-

Solution: multi-axis manifolds with honed bores; precise counterbores for O-rings; thread reliefs and surface treatments that survive assembly torque.

-

Result: seal on first assembly, stable pressure, less rework.

DFM that respects your build of materials (and budget)

Design choices with big payoffs:

-

Datums that match assembly. Use pin-and-plane schemes so metrology mirrors how parts are installed.

-

Stress-smart geometry. Thicker webs near fasteners; radiused internal corners to avoid crack starters.

-

Thin-wall realism. ≥ 1.0–1.5 mm walls in Al for stability (unless weight is critical); add ribs instead of chasing extreme walls.

-

Thread strategy. Coil inserts on soft alloys; specify thread tolerances tied to mating class, not “general.”

-

Surface where it matters. Keep Ra ≤ 0.8 µm for general functional faces; reserve ultra-smooth Ra ≤ 0.01 µm for seals/optical-adjacent surfaces to protect cost.

Typical tolerance bands (guideline):

-

Positional to datum: ±0.01–0.05 mm (part size & stack-up dependent)

-

Flatness on reference faces: 0.01–0.03 mm/100 mm

-

Concentricity/TIR on shafts: ≤ 0.01–0.02 mm

Need to push further? Critical steps can reach ±1 µm and mirror-like finishes when justified by the use case.

Materials we machine—matched to “industrial realities”

-

Aluminum (6061, 7075): light, rigid with hard anodize; ideal for frames and brackets.

-

Stainless (304/316/17-4PH): corrosion resistance for washdown areas and fixtures.

-

Carbon/tool steels: strength and wear surfaces after HT + grind.

-

Titanium (Ti-6Al-4V): high stiffness-to-weight for dynamic heads and precision carriers.

-

Engineered polymers (PEEK, POM, PC): electrical isolation, low mass, low outgassing options.

Quality & metrology—how we keep parts “honest”

-

Process sheets before chips fly. Toolpaths, cutters, speeds/feeds, coolant, probe routines, and hold points are frozen before release.

-

Smart fixturing. Vacuum plates and form-fitting soft jaws for thin-walls; dual-op schemes to keep datums consistent.

-

In-process verification. On-machine probing for tool wear and thermal drift; SPC on CTQs to stabilize yield.

-

Final checks that match function. CMM with datum simulation, functional gaging for threads/bores; cosmetic acceptance criteria for visible surfaces.

-

Documentation. Material certs, finish certs, inspection reports, and traceable labeling on request.

For optical systems: tiny details, big wins

-

cnc machined optical brackets with built-in shims or eccentric bushings for micro-adjustment.

-

cnc machining precision optical components with decluttered cable paths, low-glare blackening, and burr-free edges near optics.

-

Thermal thinking: separate heat-source mounts and optics mounts; use slot-and-pin interfaces to allow differential expansion without skew.

Two short field stories

A. “The single-station vision upgrade.”

Consolidating three cameras to a single high-throughput station introduced motion blur and calibration drift. We redesigned the bracket with a higher natural frequency, added a secondary locating pin, and tightened flatness on the rail interface. Result: first-pass yield up 4.7%, recalibration events down dramatically.

B. “Quieting the conveyor.”

A drive shaft ran hot at speed. We re-sequenced to rough-turn → stress-relieve → finish-grind, improved bearing fits, and set TIR ≤ 0.01 mm. Bearing life extended, noise dropped by 2–3 dB, and maintenance cadence lengthened.

Packaging, logistics, and scale-up

-

Pack for function: clean-room pouches for optical-adjacent parts; separators to protect finishes; desiccant for long routes.

-

Zero MOQ to volume: pilot runs capture Cp/Cpk data; the same fixtures and routings scale to batches.

-

Schedules that hold: milestone-based Gantt for complex assemblies; parallel machines for repeat SKUs.

Quick buyer’s checklist (copy into your RFQ)

- CAD + 2D with GD&T, CTQ callouts, and finish specs

- Datum scheme that mirrors your assembly

- Annual usage + ramp profile, desired lead time

- Any special clean, pack, or labeling needs

- “No-go” zones for cosmetics; acceptable blend lines

- Functional test you’ll run (we can mirror it)

Why XY-GLOBAL

-

Precision with intent: ±1 µm critical steps and Ra ≤ 0.01 µm where it matters.

-

DFM collaboration: cost-down without function-down.

-

Speed & flexibility: zero MOQ; rapid samples when timelines are tight.

-

Certified systems: ISO 9001:2015 & ISO 13485:2016, with traceable documentation.

Ready to stabilize your line? Send drawings for a 24-hour DFM review and a clear plan from prototype to production.

Share:

A380 Aluminum Die Casting: Lightweight, Durable, and High-Precision Manufacturing Solutions

Advanced CNC Machining for Titanium Medical Devices: Precision, Speed, and Certified Quality