A380 aluminum die casting is one of the most widely used processes in modern manufacturing, renowned for its excellent balance of strength, heat resistance, and castability. By injecting molten A380 aluminum alloy into precision steel molds under high pressure, manufacturers can mass-produce complex, lightweight, and dimensionally precise parts. From automotive engine blocks to electronic housings and aerospace structures, A380 die casting meets the performance and reliability demands of today's industries.

What Is Aluminum Die Casting?

Aluminum die casting is a high-speed manufacturing process where molten aluminum or aluminum alloys are injected into steel molds (dies) under high pressure. This technique enables high-volume production of complex, dimensionally accurate aluminum die casting products with tight tolerances.

Key benefits of aluminum die casting include:

-

Excellent strength-to-weight ratio

-

High thermal and electrical conductivity

-

Corrosion resistance through natural oxide layer formation

-

Cost-effective, high-speed production cycles

-

Infinite recyclability without quality loss

Because of these advantages, aluminum die casting holds a dominant position across industries such as automotive, aerospace, telecommunications, and electronics.

Aluminium Alloys for Pressure Die Casting

To meet diverse industrial requirements, manufacturers rely on aluminium alloys for pressure die casting, which combine excellent fluidity, mechanical strength, and corrosion resistance. Alloys such as A380 aluminum die casting, A383, and A356 remain the most widely used due to their balance of castability and performance. These alloys ensure stable production of thin-walled, complex components while maintaining lightweight durability.

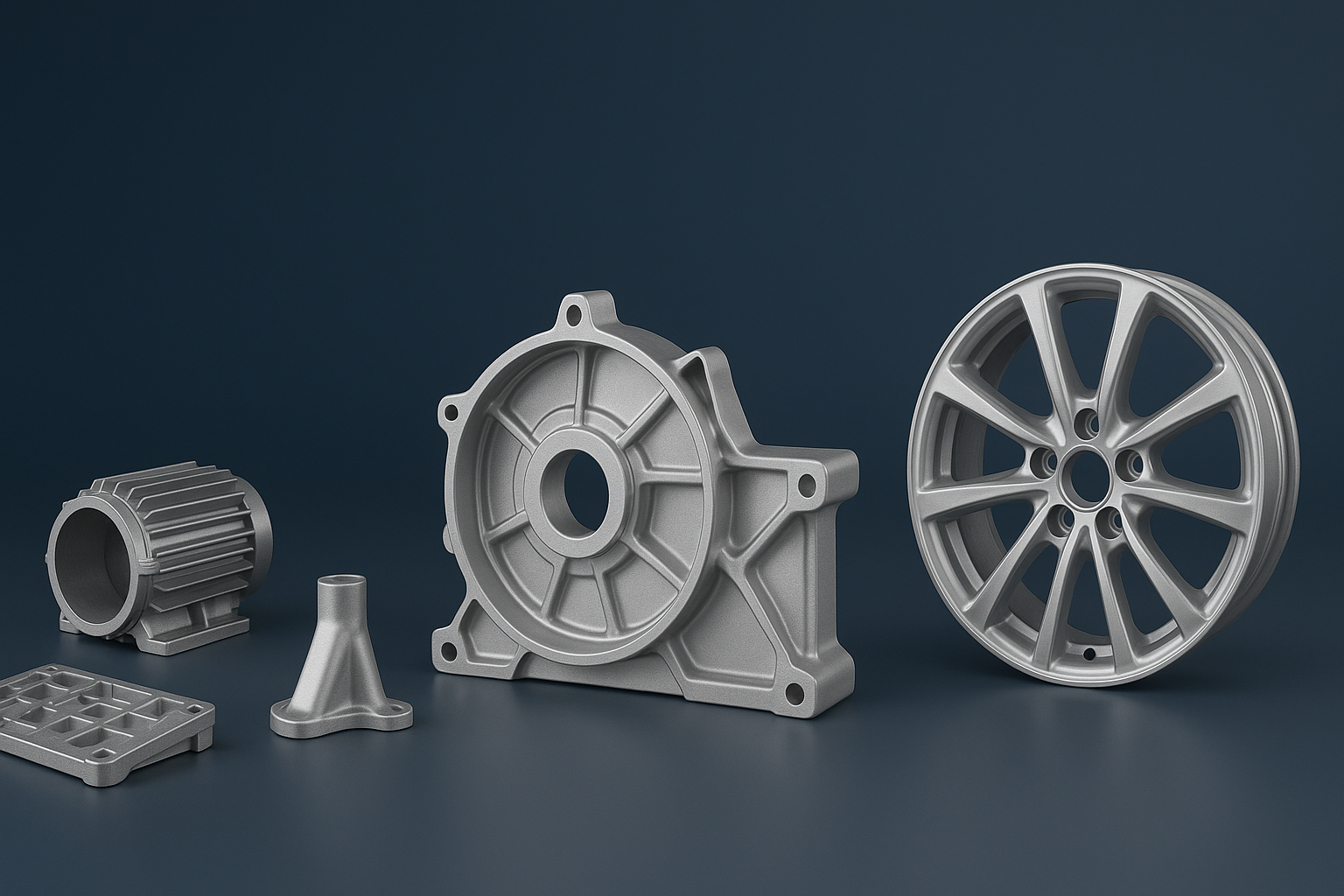

Applications of Aluminum Die Casting

Automotive Industry

-

Applications: Engine blocks, transmission housings, cylinder heads, steering components.

-

Use Cases: Lightweight designs reduce vehicle weight, improve fuel efficiency, and lower emissions.

Electronics

-

Applications: Heat sinks, device housings (laptops, smartphones), connectors.

-

Use Cases: Excellent thermal conductivity ensures efficient heat dissipation, while EMI shielding enhances device reliability.

Aerospace & Drones

-

Applications: Aircraft brackets, structural supports, UAV frames.

-

Use Cases: High strength-to-weight ratio supports safe, lightweight designs for demanding environments.

Telecommunications

-

Applications: Base station housings, antenna components, satellite casings.

-

Use Cases: Corrosion resistance and electrical conductivity make aluminum ideal for harsh outdoor environments.

Common Aluminum Die Casting Materials

| Alloy | Properties | Typical Applications |

|---|---|---|

| A383 (ADC12) | High silicon (10–12%), excellent fluidity, good for thin-wall casting | Laptop housings, LED heat sinks, electronic enclosures |

| A380 (ADC10) | High strength (≥320 MPa), copper content improves thermal resistance | Engine blocks, transmission housings, structural automotive parts |

| A356 | Low iron content, heat-treatable (T6 tensile ≥260 MPa), excellent toughness | Wheel hubs, suspension arms, aerospace brackets |

| Al-Mg Alloys | Superior corrosion resistance but challenging to cast | Marine components, outdoor enclosures |

| Al-Zn Alloys | High strength but prone to corrosion | Specialty applications requiring rigidity |

Key Property Comparison

| Property | A383 | A380 | A356 |

|---|---|---|---|

| Strength | High (~320 MPa) | Medium (~280 MPa) | Medium (~260 MPa, heat-treatable) |

| Fluidity | Excellent | Good | Moderate |

| Thermal Conductivity | ~92 W/(m·K) | ~150 W/(m·K) | ~96 W/(m·K) |

| Corrosion Resistance | Fair (due to Cu) | Excellent | Good |

| Best For | Thin-wall electronic parts | Structural automotive parts | Aerospace & mechanical parts |

Aluminum Die Casting Suppliers and Market

Choosing the right aluminum die casting suppliers is critical for product success. A reliable supplier provides not just casting capability, but also material selection guidance, DFM (Design for Manufacturability) analysis, and secondary processes such as CNC machining, surface finishing, and assembly. As a trusted supplier, XY-GLOBAL offers end-to-end services to help customers shorten development cycles and reduce costs without compromising quality.

The global market also includes many specialized enterprises, from small workshops to large-scale manufacturers such as an aluminum die casting company inc type of operation. What differentiates partners like XY-GLOBAL is not only precision tooling and international quality certifications, but also the ability to deliver tailored engineering support, rapid prototyping, and scalable mass production for clients across automotive, aerospace, and medical industries.

Why Choose Aluminum Die Casting?

-

Lightweight & Strong – Perfect for automotive and aerospace weight reduction.

-

Thermal & Electrical Efficiency – Excellent for heat sinks, housings, and power devices.

-

Durable & Corrosion Resistant – Naturally resists rust, suitable for outdoor and marine use.

-

Fast & Cost-Effective – Lower melting point allows shorter cycle times.

-

Eco-Friendly & Recyclable – Aluminum can be recycled indefinitely without performance loss.

-

Precision & Design Freedom – Enables production of thin-walled, intricate shapes with tolerances as tight as ±0.1 mm.

Conclusion

From aluminum die casting products such as heat sinks in electronics to structural parts in aerospace and automotive, aluminum die casting delivers a balance of strength, weight reduction, and thermal performance that few materials can match. Its recyclability also makes it a sustainable choice for the future of manufacturing.

If your project demands custom aluminum die casting solutions that combine lightweight durability, excellent thermal management, and cost-effective scalability, XY-GLOBAL is your ideal partner.

At XY-GLOBAL, we specialize in advanced aluminum die casting materials and tailored services to meet your exact needs. With international certifications, strict quality control, and deep experience across multiple industries, we transform your designs into high-performance products.

👉 Contact XY-GLOBAL today to work with a leading aluminum die casting supplier and bring your innovations to life.

Share:

The Precision Behind Optical & Sensor Performance

CNC Machining for Industrial Equipment