La tecnología de fundición a presión se utiliza ampliamente hoy en día, especialmente en la producción de aleaciones ligeras. Sin embargo, muchas personas aún no tienen claras las diferencias entre la fundición a baja presión (LPDC) y la fundición a alta presión (HPDC) . Para comprender mejor, veamos primero sus respectivos procesos.

Fundición a presión a baja presión (LPDC)

En la fundición a baja presión, el molde se coloca sobre un crisol sellado lleno de metal fundido. Se introduce gas comprimido en el crisol, lo que genera una baja presión (0,06–0,15 MPa) en la superficie del metal fundido. Esta presión empuja el metal hacia arriba a través de un tubo ascendente , llenando la cavidad del molde. La pieza fundida se solidifica en condiciones controladas para formar la pieza final.

Este proceso ofrece varias ventajas:

-

Alta precisión dimensional : debido a que la presión alimenta continuamente el metal fundido en la cavidad del molde, la fundición es compacta y precisa, comparable a la fundición a presión de alta presión.

-

Microestructura densa y escoria mínima : dado que el tubo ascendente extrae el metal de debajo de la superficie del líquido (donde flota la escoria), la pieza resultante es limpia y densa.

-

Buena resistencia mecánica : La baja porosidad del gas hace que las piezas sean adecuadas para el tratamiento térmico .

-

Capacidad de geometría compleja : es ideal para piezas de espesor medio (espesor de pared mínimo de alrededor de 3 mm ) con formas intrincadas.

Sin embargo, la eficiencia de producción es menor que la del moldeo a alta presión debido al proceso de llenado y solidificación más lento.

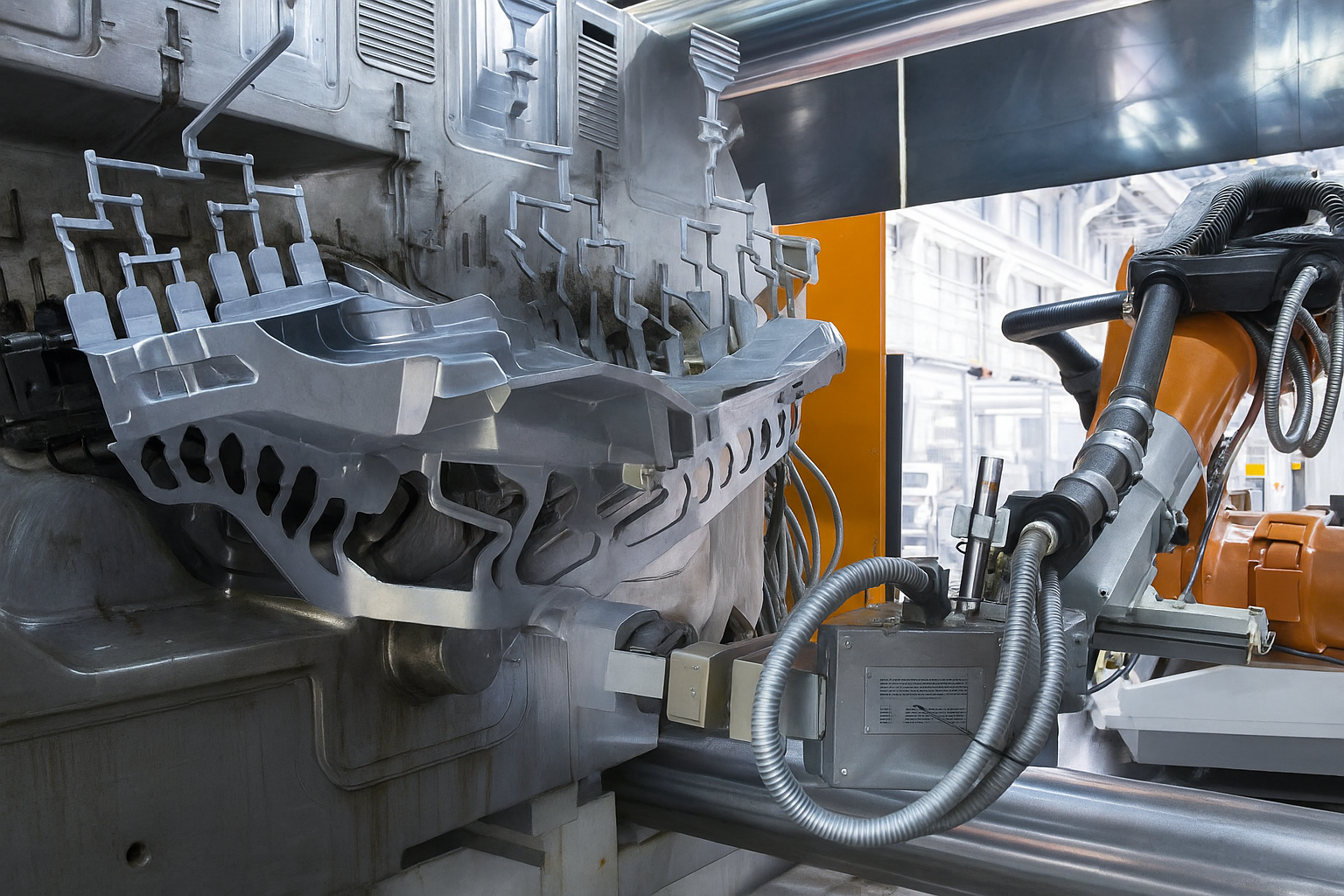

Fundición a presión de alta presión (HPDC)

En la fundición a alta presión, el metal fundido se inyecta en la cavidad del molde a muy alta presión (15-100 MPa) y alta velocidad (10-80 m/s) mediante un émbolo. El metal llena rápidamente la cavidad y se solidifica rápidamente para formar la pieza fundida.

Este proceso se caracteriza por:

-

Alta eficiencia : el tiempo de ciclo corto lo hace ideal para la producción en masa.

-

Excelente acabado superficial : gracias al rápido llenado y solidificación, la rugosidad de la superficie puede alcanzar Ra 6,3 µm y, en algunos casos , Ra 1,6 µm .

-

Capacidad de paredes delgadas : adecuado para producir piezas ultradelgadas con un espesor de pared de tan solo 0,3 a 0,5 mm .

Sin embargo, en comparación con el LPDC, las piezas de HPDC tienden a presentar mayor porosidad y menor densidad , lo que reduce ligeramente la resistencia mecánica. Además, no pueden someterse a tratamiento térmico , ya que el aire atrapado puede expandirse y causar ampollas o grietas. Las piezas de HPDC tampoco se recomiendan para aplicaciones que requieran grandes tolerancias de mecanizado (la capa superficial densa se dañaría, reduciendo la resistencia). La tolerancia de mecanizado recomendada es inferior a 0,25 mm .

Resumen

| Característica | Fundición a presión a baja presión | Fundición a presión de alta presión |

|---|---|---|

| Presión | 0,06–0,15 MPa | 15–100 MPa |

| Velocidad de llenado | Lento y controlado | Rápido (10–80 m/s) |

| Eficiencia | Moderado | Muy alto |

| Espesor de la pared | ≥ 3 mm | 0,3–0,5 mm |

| Porosidad | Bajo | Alto |

| Tratamiento térmico | Adecuado | No apto |

| Acabado de la superficie | Bien | Excelente |

| Aplicación típica | Piezas complejas de espesor medio | Producción de gran volumen y paredes delgadas |

En resumen, la fundición a presión a baja presión ofrece una calidad interna superior y es adecuada para piezas que requieren alta resistencia y posprocesamiento, mientras que la fundición a presión a alta presión se destaca en velocidad de producción y acabado de superficie , lo que la hace ideal para la fabricación a gran escala de componentes de paredes delgadas.

Compartir:

Cada detalle importa: creamos carcasas ópticas con precisión

Óptica CNC: Mecanizado de precisión para componentes ópticos