Walking into an optical laboratory for the first time can feel overwhelming, with so many optical components—mirrors, lenses, and mechanical mounts—spread across the tables. Yet, behind these seemingly complex setups lie some simple and consistent building blocks. This article introduces commonly used opto-mechanical components and optical components, along with their typical assembly methods.

1. Optical Tables

The optical table is the foundation for building advanced optical setups and supporting a wide range of optical components. Its surface is a flat stainless-steel plate with a grid of threaded holes, supported by an internal honeycomb structure for vibration isolation. The whole platform rests on pneumatic or rigid legs, which further suppress vibration.

-

Metric optical tables use M6 threaded holes on a 25 mm grid.

-

Imperial optical tables use 1/4"-20 threaded holes on a 1 inch grid.

Screws and Washers

-

Cap screws: feature an internal hex socket for Allen keys.

-

Set screws: short threaded rods with a hex socket, useful for fixing parts or joining two components.

⚠️ Safety note: Small screws easily roll off the table. Always collect them in a tray. Never bend down to pick up screws while a laser is on—eye injuries often happen this way.

For smaller, portable, or cost-sensitive setups, optical breadboards can replace full-sized optical tables and still support basic optical components.

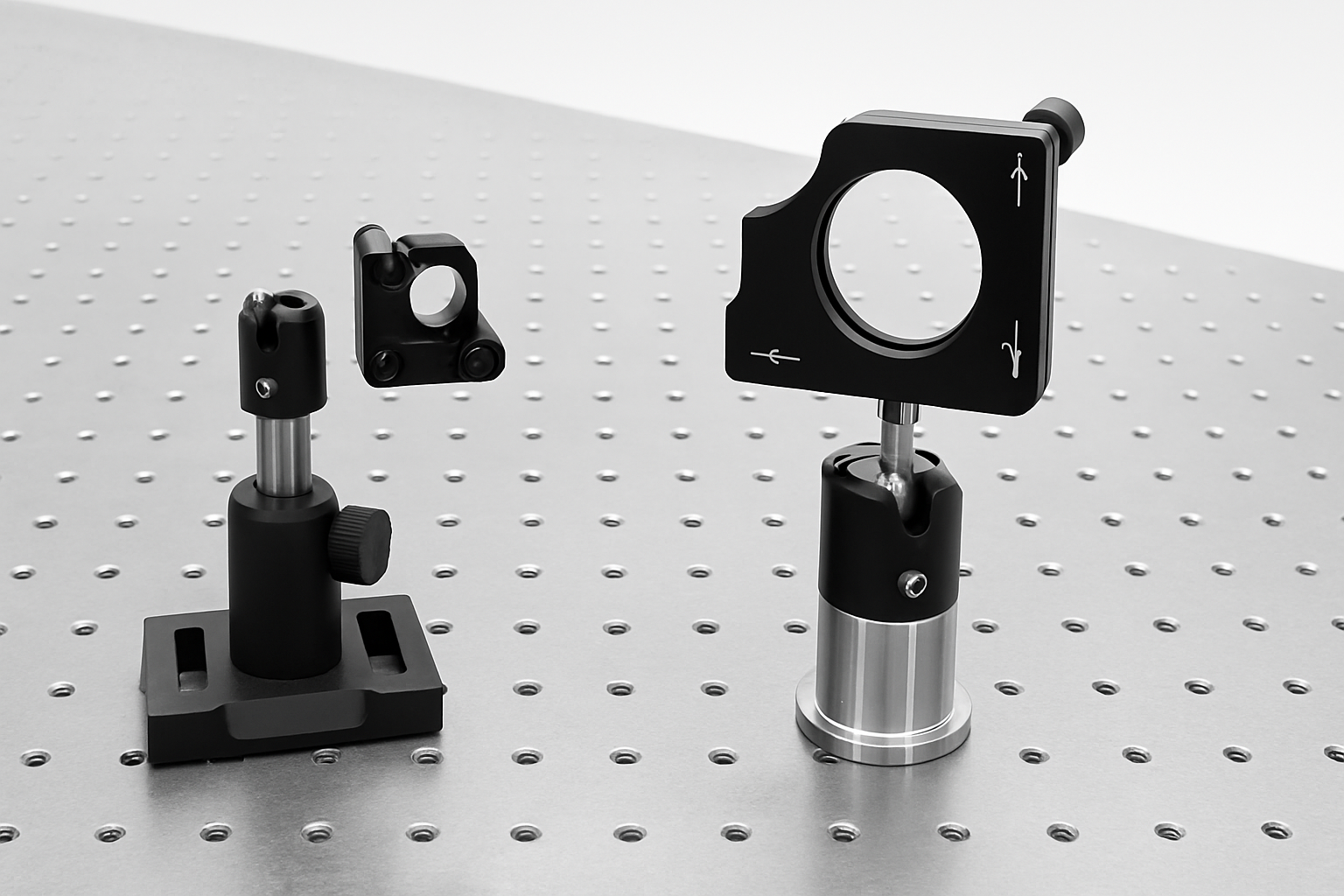

2. Optical Mounting Hardware ("Optical Lego")

Opto-mechanics are modular and often compared to LEGO blocks. They allow flexible, repeatable construction of complex systems.

Common Mounting Options

-

Post holders with round bases: fixed with cap screws and clamping forks.

-

Rotary-base holders: allow coarse rotational positioning.

-

Baseplate-mounted holders: secure posts without built-in bases.

3. Post Holders

Hollow cylindrical holders accept stainless-steel posts. Height adjustment is made by sliding the post up or down, then tightening a thumbscrew. For stability, tighten fully with a hex key after alignment.

4. Posts

Posts (Ø12.7 mm common size) control component height. They usually have an M6 tapped hole at the bottom, an M4 tapped hole at the top, and a side locking screw. Some feature engraved scales for repeatable adjustments.

5. Post Collars

Split-ring collars clamp onto posts at specific heights. They let you remove and reinsert components at the same height or rotate posts without changing vertical alignment.

6. Post Clamps

Post clamps connect two posts at 45° or 90° angles (rotary versions offer 360° adjustment). They enable 3D assemblies, e.g., mounting probes at variable heights.

7. Dovetail Rails

Rails provide linear adjustability along one axis. Post holders slide on the rail and are locked by a thumbscrew. Useful for multi-element setups like beam expanders or interferometers.

8. L-Clamps

L-shaped clamps allow fixing components from various directions, adding flexibility and stability, especially for heavy optics.

9. Flip Mounts

Flip mounts let you insert or remove optics from the beam path without losing alignment. Motorized versions are available for automation.

10. Cage and Cube Systems

Cage systems use four rods to hold components in coaxial alignment, ideal for compact, multi-layer optical assemblies such as interferometers or fiber-coupling modules.

-

Standard sizes: 16 mm, 30 mm, 60 mm, matching Ø1/2", Ø1", and Ø2" optics.

-

Components are held with cage plates, secured by side screws.

11. Optical Mounts

-

Fixed mounts: hold optics securely.

-

Kinematic mounts: allow fine tip/tilt adjustment.

-

Rotational/translation mounts: provide precise positioning.

Circular optics are often held with retaining rings or nylon-tipped screws to minimize stress-induced birefringence.

12. Mirrors

Mirrors redirect beams and are usually mounted in adjustable kinematic holders.

-

Metal-coated mirrors: broad spectral range, moderate reflectivity.

-

Dielectric mirrors: narrowband, >99% reflectivity, high damage threshold.

Two mirrors can shift a beam laterally without changing direction.

13. Polarizers and Waveplates

-

Polarizers: control polarization; thin-film versions offer extinction ratios >1000 in visible wavelengths.

-

Waveplates: modify polarization state.

-

Quarter-wave: linear ↔ circular polarization conversion.

-

Half-wave: rotate linear polarization direction.

-

Mounted in rotation mounts with angle scales for precise alignment.

14. Beamsplitters

Beamsplitters divide a beam into two.

-

Plate beamsplitters: coated glass plates.

-

Cube beamsplitters: cemented prisms.

Versions include polarizing (separate s- and p-polarizations) and non-polarizing types.

15. Filters

-

Bandpass filters: transmit specific wavelength bands.

-

Edge filters: long-pass and short-pass types.

-

Notch filters: block narrow bands.

-

ND filters: attenuate intensity (optical density, OD, defined as:

where T = transmission).

Mounted in fixed holders, flip mounts, or filter wheels.

16. Apertures and Pinholes

-

Iris diaphragms: adjustable apertures for beam shaping.

-

Precision pinholes: laser-drilled in metal foils, used in spatial filtering and confocal microscopy.

17. Lenses

-

Plano-convex (PCX): focus collimated beams.

-

Biconvex: imaging.

-

Plano-concave (PCV): diverging beams.

-

Aspheric lenses: reduce aberrations.

-

Achromatic doublets: minimize chromatic aberration.

Lens mounting: placed against a retaining lip and secured with retaining rings.

18. Microscope Objectives

Compound optics in threaded housings, widely used for microscopy, fiber coupling, and imaging.

Key Specs

-

Magnification (marked & color-coded).

-

Numerical Aperture (NA): light-gathering ability.

-

Working distance & depth of focus.

-

Infinity correction (∞ symbol): for use with tube lenses.

Magnification Color Codes

| Color | Magnification |

|---|---|

| Red | 4X, 5X |

| Yellow | 10X |

| Green | 16X, 20X |

| Turquoise | 25X |

| Light Blue | 40X, 50X |

| Cobalt Blue | 60X |

| White | 100X |

High-NA objectives improve resolution but reduce depth of focus.

✅ With these building blocks, one can quickly assemble stable and flexible optical systems—whether for basic alignment, precision measurements, or advanced experiments.

Share:

Advanced CNC Machining for Titanium Medical Devices: Precision, Speed, and Certified Quality

How Ultra-Precision Optical Lenses Are Made — The Finishing Touch of Precision Optical Coating