Jigs & Fixtures Capabilities

At XY Global, we specialize in designing and manufacturing ultra-precision jigs and fixtures tailored to your specific needs. Our solutions ensure repeatability within ±3μm, enhancing machining efficiency and reducing setup times. With ISO 9001 and ISO 13485 certifications, we serve industries including medical, optics, and automation, delivering reliable and high-quality workholding solutions.

Design & Engineering Capabilities

Strong Design Team

Independent R&D team, with an average industry experience of 10+ years.

Using software such as SolidWorks, AutoCAD, UG, MasterCAM, etc.

Can provide 3D modeling, finite element analysis (FEA), simulation testing.

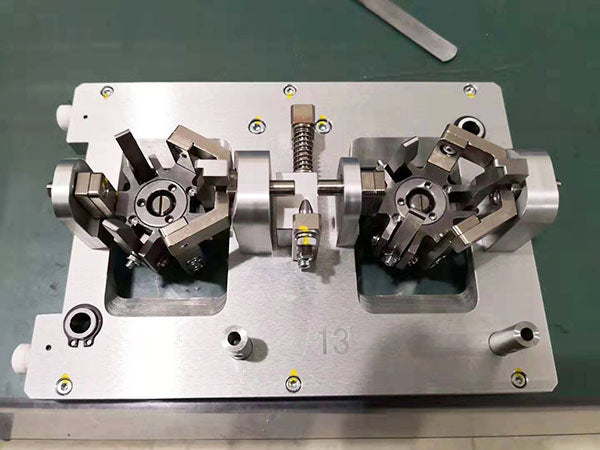

Customized Fixture Solutions

Provide professional clamping solutions based on customer product structure.

Can cope with different needs such as high precision, small batch, large batch, automated production line, etc.

Provide full-process services from solution design → trial production → production → delivery.

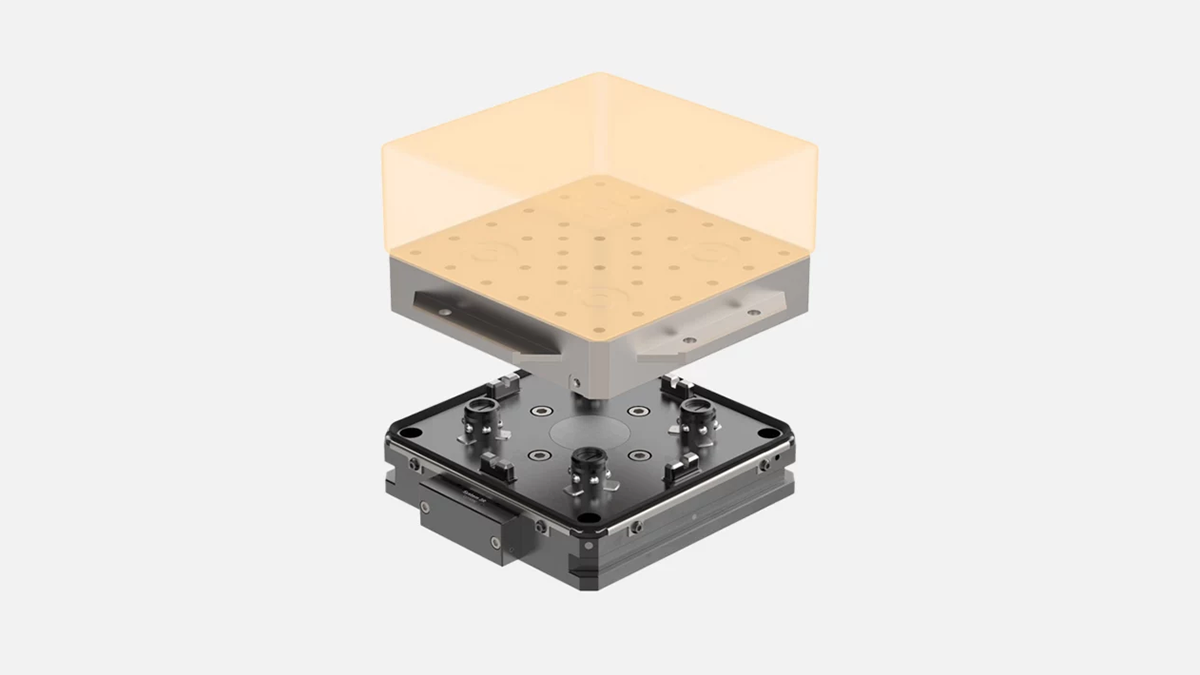

Superior Lightweight Design

At XY-GLOBAL, we design our jigs and fixtures using lightweight yet robust aluminum alloys, reinforced with steel rails for lasting durability. The result: high-performance tools that are easy to transport, quick to set up, and built to withstand demanding production environments.

Compact. Powerful. Precise.

4,500 lbs Clamping Force

70% Less Weight, Same Power

Compact Size. Maximum Efficiency.

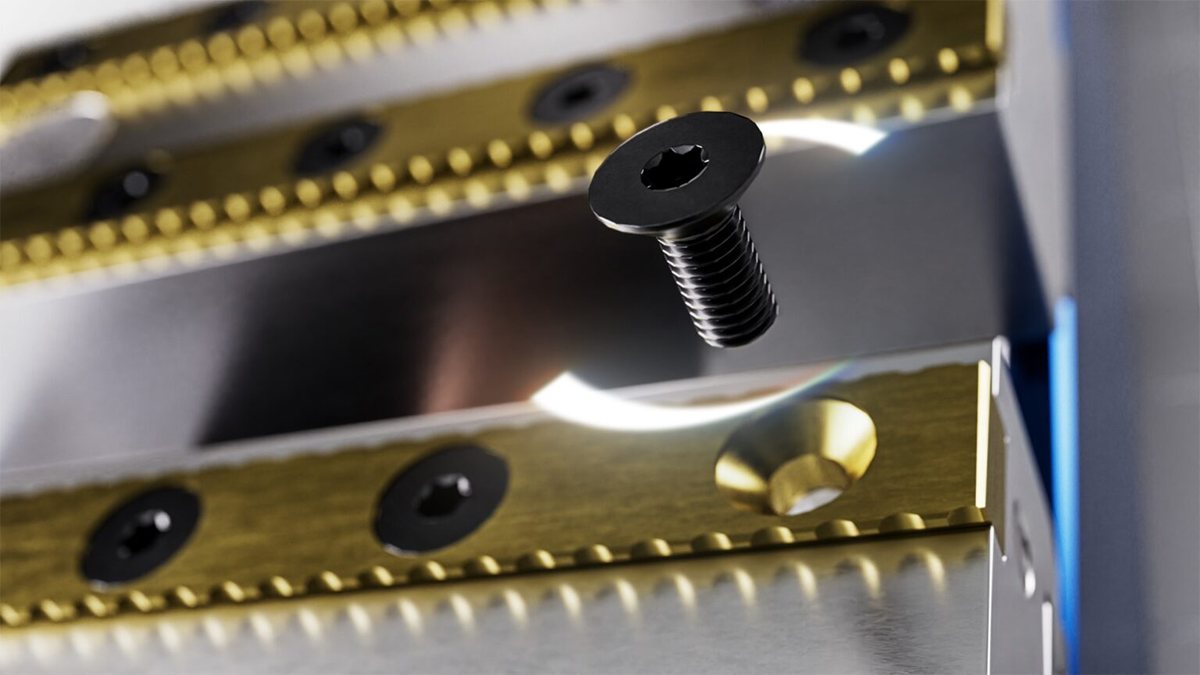

Modular Jaw Options

Select from flat, V-shape, soft, hard, or quick-change jaws to match your exact workpiece needs. All jaws are interchangeable and designed for precision, speed, and flexibility.

Jigs, Fixtures & Gauges – Professional Overview

Jigs

Designed to accurately position and secure the workpiece while guiding cutting tools. Fumetsu jigs are widely used in high-precision drilling, tapping, and other machining operations that require consistent tool alignment.

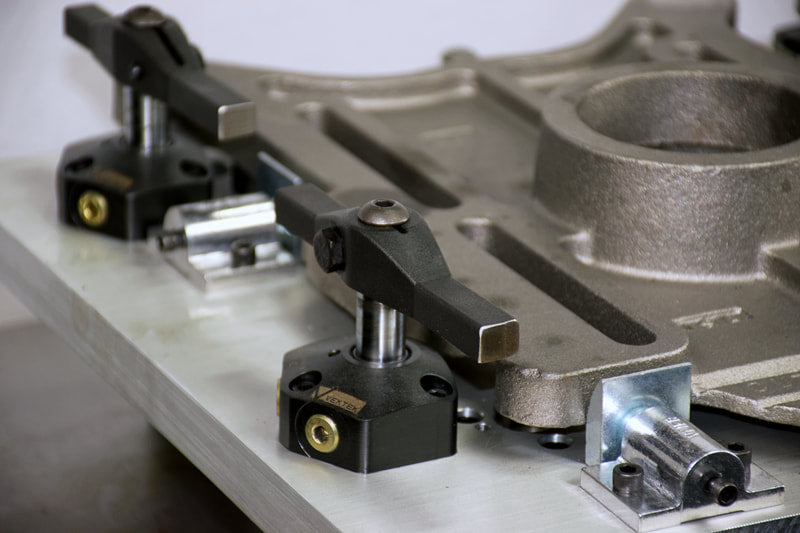

Fixtures

Engineered to hold and locate workpieces with high repeatability. Our fixtures are built for milling, turning, assembly, and inspection, ensuring stability and dimensional accuracy across complex production setups.

Gauges

Custom-built measurement tools designed for quick and reliable verification of hole diameters, shaft dimensions, surface flatness, and assembly tolerances. Fumetsu gauges streamline quality control and reduce inspection time.